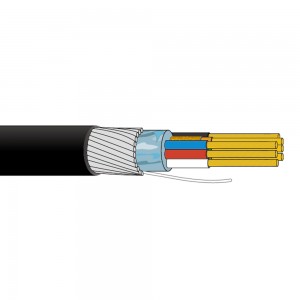

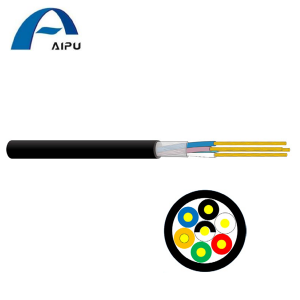

BS EN 50288-7 Communication & Control Cable LSZH ICAT Individual and collective aluminium 1mm2 & above: Class 2 Stranded Copper Conductor

Constructions

Conductor:

0.5 – 0.75mm2 : Class 5 flexible copper conductor

1mm2 & above: Class 2 stranded copper conductor

Insulation: Cross-Linked Polyethylene (XLPE) laid up in pairs Individual and Collective

Screens: Individual and collective aluminium / mylar tape screen with tinned copper drain wire

Sheath: Low Smoke Zero Halogen

Sheath Colour: Blue or Black

The maximum period of operation is 15years

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 65℃

Rated Voltage: 90V, 300V, 500V

Test Voltage (DC): 2000V Between Conductors

2000V Between Each Conductor and Armour

Reference Standards

BS EN 50288-7

BS EN 50288-1

BS EN/IEC 60332-3-24

HD383

Flame Retardant to BS EN/IEC 60332-1-2

Min. Insulation Thickness

|

Conductor Size (mm2) |

Mini. Thickness (mm) |

|||||

|

Rated Voltage |

||||||

|

90V |

Dielectric Strength |

300V |

Dielectric Strength |

500V |

Dielectric Strength |

|

|

0.5 |

0.2 |

≥0.75KVac or ≥1.5KVdc |

0.26 |

≥1.0KVac or ≥2.0KVdc |

0.44 |

≥2.0KVac or ≥3.0KVdc |

|

0.75 |

0.2 |

0.26 |

0.44 |

|||

|

1.0 |

0.26 |

0.26 |

0.44 |

|||

|

1.5 |

0.3 |

0.35 |

0.44 |

|||

General Characteristics

|

Conductor Size (mm2) |

Conductor Class |

Max. DCR (Ω/km) |

Max. Mutual Capacitance Values pF/m |

Max. Capacitance Unbalance Pairs/Quads Polyolefin (pF/500m) |

Max.L/R Ratio (μH/Ω) |

|

|

Polyolefin (nf/km) |

PVC (nf/km) |

|||||

|

0.5 |

5 |

39.7 |

150 |

250 |

500 |

25 |

|

0.75 |

5 |

26.5 |

150 |

250 |

500 |

25 |

|

1.0 |

5 |

19.8 |

150 |

250 |

500 |

25 |

|

1.5 |

2 |

13.5 |

150 |

250 |

500 |

40 |

90V, Multi-pair, PE Insulated, Overall Screened

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Screened |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

|||||

|

1 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.6 |

4.5 |

|

2 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.7 |

6.9 |

|

3 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.7 |

7.5 |

|

4 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.8 |

8.3 |

|

5 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.8 |

9.1 |

|

6 |

0.5 |

2, 5 |

0.35 |

Al-foil |

0.9 |

10.1 |

|

8 |

0.5 |

2, 5 |

0.35 |

Al-foil |

1 |

11.5 |

|

10 |

0.5 |

2, 5 |

0.35 |

Al-foil |

1.1 |

13.2 |

|

1 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.7 |

5.3 |

|

2 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.8 |

7.8 |

|

3 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.8 |

8.3 |

|

4 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.9 |

9.3 |

|

5 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.9 |

10 |

|

6 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1 |

11.1 |

|

8 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1 |

12.3 |

|

10 |

0.5 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1.1 |

14 |

|

1 |

0.75 |

2, 5 |

0.35 |

Al-foil |

0.6 |

4.9 |

|

2 |

0.75 |

2, 5 |

0.35 |

Al-foil |

0.7 |

7.6 |

|

3 |

0.75 |

2, 5 |

0.35 |

Al-foil |

0.7 |

8.2 |

|

4 |

0.75 |

2, 5 |

0.35 |

Al-foil |

0.8 |

9.1 |

|

5 |

0.75 |

2, 5 |

0.35 |

Al-foil |

0.9 |

10.2 |

|

6 |

0.75 |

2, 5 |

0.35 |

Al-foil |

1 |

11.3 |

|

8 |

0.75 |

2, 5 |

0.35 |

Al-foil |

1.1 |

12.4 |

|

10 |

0.75 |

2, 5 |

0.35 |

Al-foil |

1.2 |

14.8 |

|

1 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.7 |

5.7 |

|

2 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.8 |

8.4 |

|

3 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.9 |

9.4 |

|

4 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

0.9 |

10.1 |

|

5 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1 |

11.2 |

|

6 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1 |

12.1 |

|

8 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1.1 |

13.7 |

|

10 |

0.75 |

2, 5 |

0.35 |

Al-foil + TC Braided |

1.2 |

15.5 |

|

1 |

1 |

2, 5 |

0.4 |

Al-foil |

0.6 |

5.5 |

|

2 |

1 |

2, 5 |

0.4 |

Al-foil |

0.8 |

8.9 |

|

3 |

1 |

2, 5 |

0.4 |

Al-foil |

0.9 |

9.8 |

|

4 |

1 |

2, 5 |

0.4 |

Al-foil |

1 |

10.7 |

|

5 |

1 |

2, 5 |

0.4 |

Al-foil |

1 |

11.7 |

|

6 |

1 |

2, 5 |

0.4 |

Al-foil |

1.1 |

13 |

|

8 |

1 |

2, 5 |

0.4 |

Al-foil |

1.2 |

14.8 |

|

10 |

1 |

2, 5 |

0.4 |

Al-foil |

1.3 |

17 |

|

1 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

6.5 |

|

2 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

9.8 |

|

3 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

10.6 |

|

4 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1 |

11.5 |

|

5 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.1 |

12.7 |

|

6 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.2 |

14 |

|

8 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.3 |

15.8 |

|

10 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.3 |

17.8 |

|

1 |

1.5 |

2, 5 |

0.45 |

Al-foil |

0.7 |

6.5 |

|

2 |

1.5 |

2, 5 |

0.45 |

Al-foil |

0.9 |

10.4 |

|

3 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1 |

11.5 |

|

4 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1 |

12.4 |

|

5 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1.1 |

13.8 |

|

6 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1.2 |

15.3 |

|

8 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1.3 |

17.4 |

|

10 |

1.5 |

2, 5 |

0.45 |

Al-foil |

1.4 |

19.9 |

|

1 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

0.8 |

7.3 |

|

2 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1 |

11.4 |

|

3 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1 |

12.3 |

|

4 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1.1 |

13.4 |

|

5 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1.2 |

14.8 |

|

6 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1.3 |

16.3 |

|

8 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1.4 |

18.4 |

|

10 |

1.5 |

2, 5 |

0.45 |

Al-foil + TC Braided |

1.4 |

20.7 |

300V, Multi-pair, PE Insulated, Overall Screened

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Screened |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

|||||

|

1 |

0.5 |

2, 5 |

0.4 |

Al-foil |

0.6 |

4.7 |

|

2 |

0.5 |

2, 5 |

0.4 |

Al-foil |

0.7 |

7.3 |

|

3 |

0.5 |

2, 5 |

0.4 |

Al-foil |

0.8 |

8.1 |

|

4 |

0.5 |

2, 5 |

0.4 |

Al-foil |

0.8 |

8.7 |

|

5 |

0.5 |

2, 5 |

0.4 |

Al-foil |

0.9 |

9.7 |

|

6 |

0.5 |

2, 5 |

0.4 |

Al-foil |

1 |

10.8 |

|

8 |

0.5 |

2, 5 |

0.4 |

Al-foil |

1 |

12.1 |

|

10 |

0.5 |

2, 5 |

0.4 |

Al-foil |

1.1 |

13.9 |

|

1 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.7 |

5.5 |

|

2 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

8.1 |

|

3 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

8.7 |

|

4 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

9.7 |

|

5 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1 |

10.7 |

|

6 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1 |

11.6 |

|

8 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.1 |

13.1 |

|

10 |

0.5 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.2 |

14.9 |

|

1 |

0.75 |

2, 5 |

0.4 |

Al-foil |

0.6 |

5.3 |

|

2 |

0.75 |

2, 5 |

0.4 |

Al-foil |

0.7 |

8.3 |

|

3 |

0.75 |

2, 5 |

0.4 |

Al-foil |

0.8 |

9.2 |

|

4 |

0.75 |

2, 5 |

0.4 |

Al-foil |

0.9 |

10.1 |

|

5 |

0.75 |

2, 5 |

0.4 |

Al-foil |

1 |

11.3 |

|

6 |

0.75 |

2, 5 |

0.4 |

Al-foil |

1 |

12.3 |

|

8 |

0.75 |

2, 5 |

0.4 |

Al-foil |

1.1 |

14 |

|

10 |

0.75 |

2, 5 |

0.4 |

Al-foil |

1.2 |

16.1 |

|

1 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

7.5 |

|

2 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

9.3 |

|

3 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

10.2 |

|

4 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

11.1 |

|

5 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1 |

12.1 |

|

6 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.1 |

13.3 |

|

8 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.2 |

15 |

|

10 |

0.75 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.3 |

17.1 |

|

1 |

1 |

2, 5 |

0.4 |

Al-foil |

0.6 |

5.5 |

|

2 |

1 |

2, 5 |

0.4 |

Al-foil |

0.8 |

8.9 |

|

3 |

1 |

2, 5 |

0.4 |

Al-foil |

0.9 |

9.8 |

|

4 |

1 |

2, 5 |

0.4 |

Al-foil |

1 |

10.7 |

|

5 |

1 |

2, 5 |

0.4 |

Al-foil |

1 |

11.7 |

|

6 |

1 |

2, 5 |

0.4 |

Al-foil |

1.1 |

13 |

|

8 |

1 |

2, 5 |

0.4 |

Al-foil |

1.2 |

14.8 |

|

10 |

1 |

2, 5 |

0.4 |

Al-foil |

1.3 |

17 |

|

1 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.8 |

6.5 |

|

2 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

9.8 |

|

3 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

0.9 |

10.6 |

|

4 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1 |

11.5 |

|

5 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.1 |

12.7 |

|

6 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.2 |

14 |

|

8 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.3 |

15.8 |

|

10 |

1 |

2, 5 |

0.4 |

Al-foil + TC Braided |

1.3 |

17.8 |

|

1 |

1.5 |

2, 5 |

0.5 |

Al-foil |

0.7 |

6.7 |

|

2 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1 |

11 |

|

3 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1 |

11.8 |

|

4 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1.1 |

13 |

|

5 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1.2 |

14.4 |

|

6 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1.3 |

16 |

|

8 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1.4 |

18.2 |

|

10 |

1.5 |

2, 5 |

0.5 |

Al-foil |

1.4 |

20.6 |

|

1 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

0.8 |

7.5 |

|

2 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1 |

11.8 |

|

3 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.1 |

12.8 |

|

4 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.2 |

14 |

|

5 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.2 |

15.2 |

|

6 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.3 |

16.8 |

|

8 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.4 |

19 |

|

10 |

1.5 |

2, 5 |

0.5 |

Al-foil + TC Braided |

1.4 |

21.4 |

500V, Multi-pair, PE Insulated, Overall Screened

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Screened |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

|||||

|

1 |

0.5 |

2, 5 |

0.6 |

Al-foil |

0.6 |

5.5 |

|

2 |

0.5 |

2, 5 |

0.6 |

Al-foil |

0.8 |

8.9 |

|

3 |

0.5 |

2, 5 |

0.6 |

Al-foil |

0.9 |

9.8 |

|

4 |

0.5 |

2, 5 |

0.6 |

Al-foil |

1 |

10.7 |

|

5 |

0.5 |

2, 5 |

0.6 |

Al-foil |

1 |

11.7 |

|

6 |

0.5 |

2, 5 |

0.6 |

Al-foil |

1.1 |

13 |

|

8 |

0.5 |

2, 5 |

0.6 |

Al-foil |

1.2 |

14.8 |

|

10 |

0.5 |

2, 5 |

0.6 |

Al-foil |

1.3 |

17 |

|

1 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.8 |

6.5 |

|

2 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.9 |

9.8 |

|

3 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.9 |

10.6 |

|

4 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

11.5 |

|

5 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.1 |

12.7 |

|

6 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.2 |

14 |

|

8 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.3 |

15.8 |

|

10 |

0.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.3 |

17.8 |

|

1 |

0.75 |

2, 5 |

0.6 |

Al-foil |

0.7 |

6.1 |

|

2 |

0.75 |

2, 5 |

0.6 |

Al-foil |

0.9 |

9.7 |

|

3 |

0.75 |

2, 5 |

0.6 |

Al-foil |

0.9 |

10.5 |

|

4 |

0.75 |

2, 5 |

0.6 |

Al-foil |

1 |

11.6 |

|

5 |

0.75 |

2, 5 |

0.6 |

Al-foil |

1.1 |

12.9 |

|

6 |

0.75 |

2, 5 |

0.6 |

Al-foil |

1.2 |

14.2 |

|

8 |

0.75 |

2, 5 |

0.6 |

Al-foil |

1.3 |

16.2 |

|

10 |

0.75 |

2, 5 |

0.6 |

Al-foil |

1.3 |

18.4 |

|

1 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.8 |

6.9 |

|

2 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

10.7 |

|

3 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

11.5 |

|

4 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

12.4 |

|

5 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.1 |

13.7 |

|

6 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.2 |

15 |

|

8 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.3 |

17 |

|

10 |

0.75 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.4 |

19.4 |

|

1 |

1 |

2, 5 |

0.6 |

Al-foil |

0.7 |

6.5 |

|

2 |

1 |

2, 5 |

0.6 |

Al-foil |

0.9 |

10.4 |

|

3 |

1 |

2, 5 |

0.6 |

Al-foil |

1 |

11.5 |

|

4 |

1 |

2, 5 |

0.6 |

Al-foil |

1 |

12.4 |

|

5 |

1 |

2, 5 |

0.6 |

Al-foil |

1.1 |

13.8 |

|

6 |

1 |

2, 5 |

0.6 |

Al-foil |

1.2 |

15.3 |

|

8 |

1 |

2, 5 |

0.6 |

Al-foil |

1.3 |

17.4 |

|

10 |

1 |

2, 5 |

0.6 |

Al-foil |

1.4 |

19.9 |

|

1 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.8 |

7.3 |

|

2 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

11.4 |

|

3 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

12.3 |

|

4 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.1 |

13.4 |

|

5 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.2 |

14.8 |

|

6 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.3 |

16.3 |

|

8 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.4 |

18.4 |

|

10 |

1 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.4 |

20.7 |

|

1 |

1.5 |

2, 5 |

0.6 |

Al-foil |

0.8 |

7.3 |

|

2 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1 |

11.6 |

|

3 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1 |

12.6 |

|

4 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1.1 |

13.8 |

|

5 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1.2 |

15.4 |

|

6 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1.3 |

17 |

|

8 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1.4 |

19.3 |

|

10 |

1.5 |

2, 5 |

0.6 |

Al-foil |

1.4 |

22 |

|

1 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

0.8 |

7.9 |

|

2 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1 |

12.6 |

|

3 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.1 |

13.6 |

|

4 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.2 |

14.8 |

|

5 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.2 |

16.4 |

|

6 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.3 |

17.8 |

|

8 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.4 |

20.1 |

|

10 |

1.5 |

2, 5 |

0.6 |

Al-foil + TC Braided |

1.4 |

22.7 |