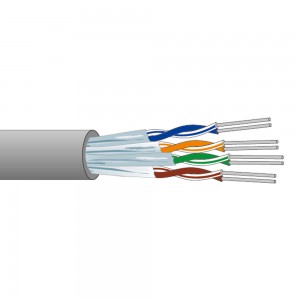

Liycy Bare Copper Class 5 to IEC 60228 Screened Data Transmission Cable Braid Instrumentation and Control Cable Electrical Wire

CABLE CONSTRUCTON

1.Conductor: bare copper conductor, fine wired stranded, class 5 acc. to IEC 60228 / HD 383 / DIN VDE 0295

2.Insulation: PVC compound of type TI2, acc. to DIN VDE 0281 part 1

conductors stranded in layers, core colour marking defined acc. to DIN 47100, without repeating of colors

3. Separator: Polyester tape

4. Electrostatic screen: braid of tinned copper wires with approx. 85% coverage

5. Sheath: PVC-compound TM2 acc. to DIN VDE 0281 part 1 sheath colour: light gray, gray or blue

TECHNICAL DATA

Temperature range:

• during installation and application with bending: -5 °C up to +70 °C

• fixed installed: -30 °C up to +70 °C

Rated voltage: 250 V

Insulation resistance: min. 100 MΩ x km

Inductance: approx. 0.7 mH/km

Impedance: approx. 85 Ω

Mutual capacitance: (at 800 Hz) max

• core – core: 120 nF/km

• core – screen: 160 nF/km

|

Conductor cross-section area |

0.14 mm2 |

≥ 0.25 mm2 |

|

Operating voltage, max. (V) |

300 |

500 |

|

Test voltage, max. (V) |

1200 |

1500 |

Flexible cable with protective screen against electromagnetic impacts, for transmission of analogue and digital signals, suitable for fixed and mobile installations in device production, for electronic, computer and measurement systems, in mobile and production conveyors, for office devices. Usage with shifting is only possible if not exposed to stress and mechanical loads. Laid in dry and damp premises, but outdoor application is not recommended, except in special cases under protection against direct sunlight. Not for direct laying in ground or water, not intended for supply purposes. Oil resistant.

CONDUCTOR CONSTRUCTION & REISISTANCE

|

Conductor cross-section |

No. of wires x diameter |

Conductor resistance at 20℃ max. |

|

N x mm2 |

n x mm |

Ω/km |

|

0.14 |

8 x 0.15 |

138.0 |

|

0.25 |

14 x 0.15 |

77.8 |

|

0.34 |

19 x 0.15 |

56.0 |

|

0.5 |

16 x 0.20 |

39.0 |

|

0.75 |

24 x 0.20 |

26.0 |

|

1 |

32 x 0.20 |

19.5 |

|

1.5 |

30 x 0.25 |

13.3 |

CABLE DIMENSION

|

Number of cores x Cross section area |

Cable outer diameter, approx |

Cu weight |

Cable weight |

|

N x mm2 |

mm |

Kg/km |

Kg/km |

|

2 x 0.14 |

3.9 |

12 |

20 |

|

3 x 0.14 |

4.1 |

13 |

28 |

|

4 x 0.14 |

4.3 |

14.3 |

33 |

|

5 x 0.14 |

4.6 |

15.5 |

38 |

|

6 x 0.14 |

4.9 |

18.2 |

38 |

|

7 x 0.14 |

4.9 |

19 |

49 |

|

8 x 0.14 |

5.8 |

21.2 |

56 |

|

10 x 0.14 |

6.1 |

28.5 |

66 |

|

12 x 0.14 |

6.3 |

30.4 |

78 |

|

14 x 0.14 |

6.7 |

32 |

80 |

|

15 x 0.14 |

6.9 |

37.8 |

86 |

|

16 x 0.14 |

7 |

43 |

90 |

|

18 x 0.14 |

7.3 |

48.8 |

95 |

|

20 x 0.14 |

7.7 |

53.9 |

100 |

|

21 x 0.14 |

7.9 |

55.5 |

105 |

|

24 x 0.14 |

8.3 |

61 |

112 |

|

25 x 0.14 |

8.5 |

63 |

120 |

|

28 x 0.14 |

8.5 |

66.1 |

141 |

|

30 x 0.14 |

8.7 |

69 |

155 |

|

36 x 0.14 |

9.3 |

83 |

170 |

|

40 x 0.14 |

10.4 |

87.5 |

178 |

|

44 x 0.14 |

10.7 |

110.5 |

185 |

|

50 x 0.14 |

11.1 |

122.5 |

195 |

|

2 x 0.25 |

4.5 |

16 |

32 |

|

3 x 0.25 |

4.7 |

21 |

37 |

|

4 x 0.25 |

5 |

24 |

41.3 |

|

5 x 0.25 |

5.6 |

29 |

51.2 |

|

6 x 0.25 |

6 |

30 |

58 |

|

7 x 0.25 |

6 |

37 |

65 |

|

8 x 0.25 |

7.1 |

42 |

73 |

|

10 x 0.25 |

7.5 |

46 |

82 |

|

12 x 0.25 |

7.7 |

53 |

98 |

|

14 x 0.25 |

8 |

59 |

99 |

|

15 x 0.25 |

8.3 |

61 |

111 |

|

16 x 0.25 |

8.4 |

64 |

119 |

|

18 x 0.25 |

8.8 |

83 |

125 |

|

20 x 0.25 |

9.3 |

88 |

136 |

|

21 x 0.25 |

9.6 |

93 |

161 |

|

25 x 0.25 |

10.7 |

114 |

172 |

|

28 x 0.25 |

10.8 |

126 |

181.1 |

|

32 x 0.25 |

11.4 |

138 |

203 |

|

36 x 0.25 |

11.8 |

148 |

220 |

|

40 x 0.25 |

12.7 |

157 |

248 |

|

50 x 0.25 |

13.8 |

178 |

318 |

|

61 x 0.25 |

15 |

205 |

365.2 |

|

2 x 0.34 |

4.9 |

21 |

37 |

|

3 x 0.34 |

5.1 |

27 |

42 |

|

4 x 0.34 |

5.7 |

28 |

52 |

|

5 x 0.34 |

6.2 |

30 |

60 |

|

6 x 0.34 |

6.8 |

45 |

64 |

|

7 x 0.34 |

6.8 |

48 |

75 |

|

8 x 0.34 |

7.8 |

52 |

94 |

|

10 x 0.34 |

8.3 |

74 |

105 |

|

12 x 0.34 |

8.5 |

80 |

123 |

|

14 x 0.34 |

8.9 |

86 |

154 |

|

15 x 0.34 |

9.2 |

90 |

155 |

|

16 x 0.34 |

9.4 |

94 |

160 |

|

18 x 0.34 |

10.2 |

103 |

173 |

|

20 x 0.34 |

10.7 |

112 |

192 |

|

21 x 0.34 |

11.1 |

116 |

199.2 |

|

25 x 0.34 |

11.9 |

135 |

259 |

|

28 x 0.34 |

12 |

153 |

280 |

|

30 x 0.34 |

12.3 |

159 |

291.1 |

|

32 x 0.34 |

13 |

165 |

305 |

|

36 x 0.34 |

13.4 |

179 |

331 |

|

40 x 0.34 |

14.8 |

200 |

365 |

|

50 x 0.34 |

15.9 |

235 |

431 |

|

2 x 0.5 |

5.6 |

29 |

47 |

|

3 x 0.5 |

5.9 |

38 |

55 |

|

4 x 0.5 |

6.3 |

43 |

70 |

|

5 x 0.5 |

7 |

51 |

90 |

|

6 x 0.5 |

7.6 |

59 |

104 |

|

7 x 0.5 |

7.6 |

65 |

112 |

|

8 x 0.5 |

8.7 |

70 |

120 |

|

10 x 0.5 |

9.3 |

88 |

139 |

|

12 x 0.5 |

9.6 |

99 |

177 |

|

18 x 0.5 |

11.8 |

134 |

239 |

|

20 x 0.5 |

12.1 |

149 |

276 |

|

25 x 0.5 |

13.7 |

211 |

352 |

|

30 x 0.5 |

14.5 |

230 |

397 |

|

2 x 0.75 |

6 |

38 |

53 |

|

3 x 0.75 |

6.3 |

49 |

65 |

|

4 x 0.75 |

7 |

58 |

79 |

|

5 x 0.75 |

7.6 |

67 |

109 |

|

7 x 0.75 |

8.2 |

100 |

156 |

|

10 x 0.75 |

10.5 |

130 |

187 |

|

12 x 0.75 |

10.8 |

154 |

218 |

|

18 x 0.75 |

13 |

195 |

327 |

|

25 x 0.75 |

15.3 |

280 |

454 |

|

30 x 0.75 |

15.8 |

312 |

486 |

|

2 x 1.0 |

6.3 |

43 |

72 |

|

3 x 1.0 |

6.8 |

56 |

90 |

|

4 x 1.0 |

7.3 |

68 |

109 |

|

5 x 1.0 |

8 |

79 |

126 |

|

7 x 1.0 |

8.6 |

118 |

171 |

|

10 x 1.0 |

11.1 |

140 |

228 |

|

12 x 1.0 |

11.4 |

168 |

259 |

|

18 x 1.0 |

13.4 |

252 |

389 |

|

25 x 1.0 |

16.2 |

335 |

517 |

|

2 x 1.5 |

7.1 |

58 |

90 |

|

3 x 1.5 |

7.5 |

74 |

115 |

|

4 x 1.5 |

4 x 1.5 |

108 |

129 |

|

5 x 1.5 |

5 x 1.5 |

129 |

176 |

|

7 x 1.5 |

7 x 1.5 |

164 |

220 |

|

12 x 1.5 |

12 x 1.5 |

254 |

376 |

|

18 x 1.5 |

15.3 |

350 |

519 |

|

25 x 1.5 |

17.9 |

550 |

901 |