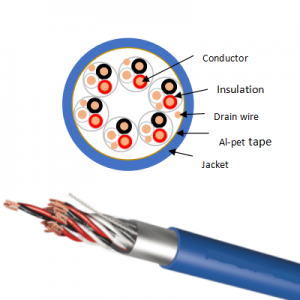

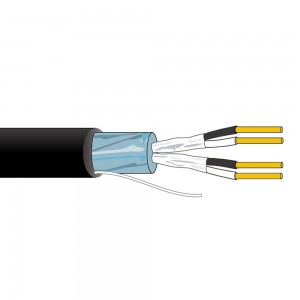

BS5308 Part1 Type1 Instrumentation Cable PVC ICAT Multi-Conductor Audio Control and Instrumentation Cable

Application

Manufactured to PAS5308, Instrumentation cables are intrinsically safe and designed for use in communication and instrumentation applications in and around process industries for transmission of signals in control systems. The signals can be analogue or digital from a variety of sensors and transducers.

Feature:

General Characteristics

|

Conductor Size (mm2) |

Conductor Class |

Max. DCR (Ω/km) |

Max. Mutual Capacitance Values pF/m |

Max. Capacitance Unbalance at 1KHz (pF/250m) |

Max.L/R Ratio (μH/Ω) |

|

|

Cables with Collective Screens (except 1pair & 2pairs) |

1Pair & 2Pairs Cables Collectively Screened & All Cables with Individual Pair Screens |

|||||

|

0.5 |

1 |

36.8 |

75 |

115 |

250 |

25 |

|

1.0 |

1 |

18.4 |

75 |

115 |

250 |

25 |

|

0.5 |

5 |

39.7 |

75 |

115 |

250 |

25 |

|

1.5 |

2 |

12.3 |

85 |

120 |

250 |

40 |

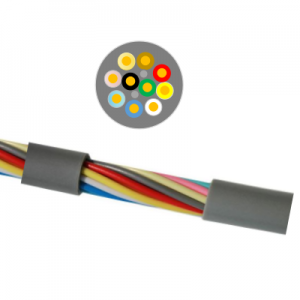

Identification of Cable Pairs

|

Pair No. |

Colour |

Pair No. |

Colour |

||

|

1 |

Black |

Blue |

11 |

Black |

Red |

|

2 |

Black |

Green |

12 |

Blue |

Red |

|

3 |

Blue |

Green |

13 |

Green |

Red |

|

4 |

Black |

Brown |

14 |

Brown |

Red |

|

5 |

Blue |

Brown |

15 |

White |

Red |

|

6 |

Green |

Brown |

16 |

Black |

Orange |

|

7 |

Black |

White |

17 |

Blue |

Orange |

|

8 |

Blue |

White |

18 |

Green |

Orange |

|

9 |

Green |

White |

19 |

Brown |

Orange |

|

10 |

Brown |

White |

20 |

White |

Orange |

PAS/BS5308 Part 1 Type 1: Collectively Screened Unarmoured

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

||||

|

1 |

0.5 |

1 |

0.5 |

0.8 |

5.3 |

|

2 |

0.5 |

1 |

0.5 |

0.8 |

6.1 |

|

5 |

0.5 |

1 |

0.5 |

1.1 |

10.6 |

|

10 |

0.5 |

1 |

0.5 |

1.2 |

14.0 |

|

15 |

0.5 |

1 |

0.5 |

1.2 |

16.1 |

|

20 |

0.5 |

1 |

0.5 |

1.3 |

18.4 |

|

1 |

1 |

1 |

0.6 |

0.8 |

6.4 |

|

2 |

1 |

1 |

0.6 |

0.8 |

7.4 |

|

5 |

1 |

1 |

0.6 |

1.1 |

13.2 |

|

10 |

1 |

1 |

0.6 |

1.2 |

17.4 |

|

15 |

1 |

1 |

0.6 |

1.3 |

20.3 |

|

20 |

1 |

1 |

0.6 |

1.5 |

23.4 |

|

1 |

0.5 |

5 |

0.6 |

0.8 |

6.0 |

|

2 |

0.5 |

5 |

0.6 |

0.8 |

6.9 |

|

5 |

0.5 |

5 |

0.6 |

1.1 |

12.1 |

|

10 |

0.5 |

5 |

0.6 |

1.2 |

16.2 |

|

15 |

0.5 |

5 |

0.6 |

1.3 |

18.8 |

|

20 |

0.5 |

5 |

0.6 |

1.3 |

21.3 |

|

1 |

1.5 |

2 |

0.6 |

0.8 |

7.3 |

|

2 |

1.5 |

2 |

0.6 |

0.9 |

8.7 |

|

5 |

1.5 |

2 |

0.6 |

1.2 |

15.4 |

|

10 |

1.5 |

2 |

0.6 |

1.3 |

20.6 |

|

15 |

1.5 |

2 |

0.6 |

1.5 |

24.2 |

|

20 |

1.5 |

2 |

0.6 |

1.5 |

27.5 |

PAS/BS5308 Part 1 Type 1: Individually & Collectively Screened Unarmoured

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

||||

|

2 |

0.5 |

1 |

0.5 |

0.9 |

8.5 |

|

5 |

0.5 |

1 |

0.5 |

0.9 |

10.9 |

|

10 |

0.5 |

1 |

0.5 |

1.1 |

15.6 |

|

15 |

0.5 |

1 |

0.5 |

1.2 |

18.1 |

|

20 |

0.5 |

1 |

0.5 |

1.3 |

20.4 |

|

2 |

1 |

1 |

0.6 |

0.9 |

10.3 |

|

5 |

1 |

1 |

0.6 |

1.0 |

13.5 |

|

10 |

1 |

1 |

0.6 |

1.2 |

19.4 |

|

15 |

1 |

1 |

0.6 |

1.4 |

22.7 |

|

20 |

1 |

1 |

0.6 |

1.5 |

25.7 |

|

2 |

0.5 |

5 |

0.6 |

0.9 |

9.7 |

|

5 |

0.5 |

5 |

0.6 |

1.0 |

12.6 |

|

10 |

0.5 |

5 |

0.6 |

1.2 |

18.0 |

|

15 |

0.5 |

5 |

0.6 |

1.3 |

20.9 |

|

20 |

0.5 |

5 |

0.6 |

1.4 |

23.6 |

|

2 |

1.5 |

2 |

0.6 |

1.0 |

12.1 |

|

5 |

1.5 |

2 |

0.6 |

1.1 |

15.8 |

|

10 |

1.5 |

2 |

0.6 |

1.4 |

22.9 |

|

15 |

1.5 |

2 |

0.6 |

1.5 |

26.6 |

|

20 |

1.5 |

2 |

0.6 |

1.6 |

30.1 |