Mvvs Fine Wire Stranded Bare Copper Wire Conductor PVC Insulation and Sheath Data Transmission Cable with Screen Braiding

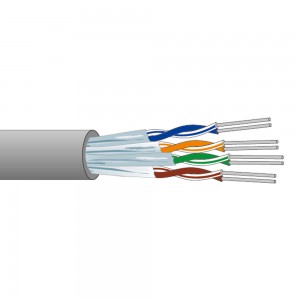

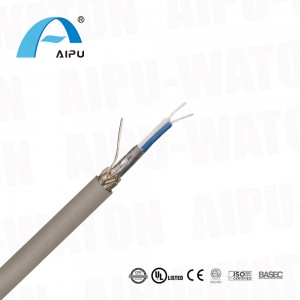

CONSTRUCTION

Conductor: Fine wire stranded bare copper wire

Insulation: PVC (Polyvinyl Chloride)

Screen:0. 12 tinned annealed copper wire braiding

Sheath:PVC (Polyvinyl Chloride)

CORE COLOUR

| Core | Colour | Core | Colour | Core | Colour | Core | Colour |

| 1 | White | 11 | Purple | 21 | Brown | 31 | Blue |

| 2 | Red | 12 | Grey | 22 | Pink | 32 | Yellow |

| 3 | Black | 13 | Light Green | 23 | Light Blue | 33 | Brown |

| 4 | Green | 14 | Cream | 24 | Orange | 34 | Pink |

| 5 | Blue | 15 | White | 25 | Purple | 35 | Light Blue |

| 6 | Yellow | 16 | Red | 26 | Grey | 36 | Orange |

| 7 | Brown | 17 | Black | 27 | Light Green | 37 | Purple |

| 8 | Pink | 18 | Green | 28 | Cream | 38 | Grey |

| 9 | Light Blue | 19 | Blue | 29 | White | 39 | Light Green |

| 10 | Orange | 20 | Yellow | 30 | Green | 40 | Cream |

CHARACTERISTICS

Voltage Rating:60V

Temperature Rating:-25°C to +60°C

Working Voltage:Up to 100V

APPLICATION

MVVS data transmission cables are used in the electronics of computer systems, electronic control equipment, etc. Copper screen braiding protects against high frequency interference. It is suitable for free, non-continuous movement without strain relief, such as microphone, signal lines, etc

ELECTRICAL CHARATERISTIC

| Cross sectional area | mm2 | 0. 18 | 0.25 | 0.3 | 0.5 | 0.75 | 1.25 | 2.0 |

| Construction of conductor | mm | 10/0.15 | 14/0.15 | 17/0.15 | 29/0.15 | 43/0.15 | 41/0.20 | 40/0.25 |

| Diameter of Insulation | mm | 1.05 | 1.25 | 1.5 | 2.0 | 2.1 | 2.7 | 3.0 |

| Test voltage | V/min | 100 | 100 | 100 | 100 | 1000 | 1000 | 1000 |

| Conductor resistance 30°C | Mok/km | 108 | 76 | 61.9 | 37.1 | 24.8 | 14.9 | 9.5 |

| Insulation resistance 30°C | Mok/km | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Conductor | Insulation | No. of core | Sheath | Approx. Weight | ||||

| Nominal Sectional Area | Wire no./dia. |

Diameter | Thickness | Diameter | Thickness | Diameter | ||

| mm2 | mm | mm | mm | mm | mm | mm | ||

| 0. 18 | 10/0. 15 | 0.55 | 0.35 | 1.25 | 2 | 0.4 | 3.3 | 18 |

| 3 | 0.6 | 3.9 | 25 | |||||

| 4 | 0.7 | 4.4 | 33 | |||||

| 6 | 0.9 | 5.6 | 53 | |||||

| 8 | 0.9 | 5.9 | 60 | |||||

| 10 | 0.9 | 6.8 | 72 | |||||

| 12 | 0.9 | 7.0 | 80 | |||||

| 16 | 1.1 | 8.1 | 102 | |||||

| 20 | 1.1 | 8.6 | 121 | |||||

| 25 | 1.1 | 9.9 | 143 | |||||

| 30 | 1.1 | 10.2 | 156 | |||||

| 0.25 | 14/0. 15 | 0.65 | 0.4 | 1.45 | 2 | 0.8 | 4.5 | 32 |

| 3 | 0.8 | 4.7 | 44 | |||||

| 4 | 0.9 | 5.3 | 53 | |||||

| 6 | 0.9 | 6.2 | 62 | |||||

| 8 | 0.9 | 6.6 | 77 | |||||

| 10 | 1.0 | 7.8 | 91 | |||||

| 12 | 1.0 | 8.0 | 102 | |||||

| 16 | 1.1 | 9.0 | 126 | |||||

| 20 | 1.2 | 9.9 | 145 | |||||

| 25 | 1.3 | 11.5 | 187 | |||||

|

0.3 |

17/0. 15 |

0.7 |

0.4 |

1.5 |

2 | 0.8 | 5.2 | 36 |

| 3 | 0.8 | 5.4 | 48 | |||||

| 4 | 1.0 | 6.2 | 58 | |||||

| 5 | 1.0 | 6.7 | 61 | |||||

| 6 | 1.0 | 7.1 | 68 | |||||

| 8 | 1.0 | 7.8 | 84 | |||||

| 10 | 1.0 | 8.5 | 100 | |||||

| 12 | 1.2 | 9.1 | 112 | |||||

| 16 | 1.3 | 10.3 | 138 | |||||

| 20 | 1.3 | 11.0 | 158 | |||||

| 30 | 1.3 | 12.5 | 243 | |||||

|

0.5 |

29/0. 15 |

1.0 |

0.5 |

2.0 |

2 | 1.0 | 6.4 | 26 |

| 3 | 1.0 | 6.8 | 62 | |||||

| 4 | 1.0 | 7.3 | 72 | |||||

| 6 | 1.0 | 8.5 | 81 | |||||

| 7 | 1.0 | 8.5 | 100 | |||||

| 8 | 1.0 | 9.5 | 108 | |||||

| 10 | 1.2 | 10.6 | 129 | |||||

| 12 | 1.2 | 11.0 | 148 | |||||

| 16 | 1.3 | 13.0 | 168 | |||||

| 20 | 1.5 | 13.7 | 216 | |||||

| 30 | 1.5 | 16.0 | 387 | |||||

|

0.75 |

43/0. 15 |

1.1 |

0.5 |

2.1 |

2 | 1.0 | 6.9 | 67 |

| 3 | 1.0 | 7.2 | 78 | |||||

| 4 | 1.0 | 8.0 | 94 | |||||

| 5 | 1.2 | 8.9 | 106 | |||||

| 6 | 1.2 | 9.5 | 119 | |||||

| 7 | 1.2 | 9.5 | 131 | |||||

| 8 | 1.2 | 10.4 | 150 | |||||

| 10 | 1.3 | 11.5 | 191 | |||||

| 12 | 1.3 | 12. 1 | 213 | |||||

| 14 | 1.3 | 12.8 | 248 | |||||

| 16 | 1.5 | 13.7 | 275 | |||||

| 20 | 1.5 | 15.0 | 335 | |||||

|

1.25 |

41/0.20 |

1.5 |

0.6 |

2.7 |

2 | 1.0 | 8.1 | 95 |

| 3 | 1.0 | 8.5 | 114 | |||||

| 4 | 1.0 | 9.3 | 121 | |||||

| 5 | 1.2 | 10.4 | 165 | |||||

| 6 | 1.2 | 11.0 | 186 | |||||

| 7 | 1.2 | 11.0 | 204 | |||||

| 8 | 1.4 | 12.0 | 234 | |||||

| 10 | 1.4 | 13.5 | 287 |

| 12 | 1.6 | 14.3 | 334 | |||||

|

2.0 |

40/0.25 |

1.8 |

0.6 |

3.0 |

2 | 1.0 | 8.7 | 115 |

| 3 | 1.0 | 9.0 | 135 | |||||

| 4 | 1.0 | 10.0 | 170 | |||||

| 5 | 1.2 | 11.5 | 203 | |||||

| 6 | 1.2 | 12.5 | 234 | |||||

| 7 | 1.4 | 12.5 | 258 | |||||

| 8 | 1.4 | 13.5 | 295 | |||||

| 10 | 1.6 | 15 | 362 | |||||

| 12 | 1.6 | 15.5 | 432 |

| Conductor | Insulation | No. ofcore | Sheath | Approx. Weight | ||||

| Nominal Sectional Area | Wireno./dia. | Diameter | Thickness | Diameter | Thickness | Diameter | ||

| mm2 | mm | mm | mm | mm | mm | mm | ||

|

0.75 |

43/0. 15 |

1.1 |

0.5 |

2.1 |

2 | 1.0 | 6.9 | 67 |

| 3 | 1.0 | 7.2 | 78 | |||||

| 4 | 1.0 | 8.0 | 94 | |||||

| 5 | 1.2 | 8.9 | 106 | |||||

| 6 | 1.2 | 9.5 | 119 | |||||

| 7 | 1.2 | 9.5 | 131 | |||||

| 8 | 1.2 | 10.4 | 150 | |||||

| 10 | 1.3 | 11.5 | 191 | |||||

| 12 | 1.3 | 12. 1 | 213 | |||||

| 14 | 1.3 | 12.8 | 248 | |||||

| 16 | 1.5 | 13.7 | 275 | |||||

| 20 | 1.5 | 15.0 | 335 | |||||

|

1.25 |

41/0.20 |

1.5 |

0.6 |

2.7 |

2 | 1.0 | 8.1 | 95 |

| 3 | 1.0 | 8.5 | 114 | |||||

| 4 | 1.0 | 9.3 | 121 | |||||

| 5 | 1.2 | 10.4 | 165 | |||||

| 6 | 1.2 | 11.0 | 186 | |||||

| 7 | 1.2 | 11.0 | 204 | |||||

| 8 | 1.4 | 12.0 | 234 | |||||

| 10 | 1.4 | 13.5 | 287 | |||||

| 12 | 1.6 | 14.3 | 334 | |||||

| 2.0 | 40/0.25 | 1.8 | 0.6 | 3.0 | 2 | 1.0 | 8.7 | 115 |

| 3 | 1.0 | 9.0 | 135 | |||||

| 4 | 1.0 | 10.0 | 170 | |||||

| 5 | 1.2 | 11.5 | 203 | |||||

| 6 | 1.2 | 12.5 | 234 | |||||

| 7 | 1.4 | 12.5 | 258 | |||||

| 8 | 1.4 | 13.5 | 295 | |||||

| 10 | 1.6 | 15 | 362 | |||||

| 12 | 1.6 | 15.5 | 432 |