TUV SAA certificates 1*2*1.5mm2 Armoured Instrumentation Cable LSZH Sheath with TC Drain wire

Scan the qr code to get product catalogue.

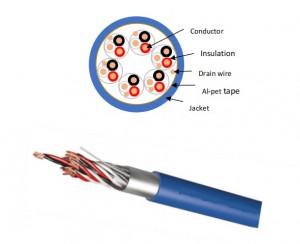

Constructions

Conductor: Plain Annealed Copper Conductors

Insulation: Polyethylene (PET) Laid up to form pairs

Screen: Collective aluminium / mylar tape screen complete with 0.5mm drain wire

Bedding: Low Smoke Zero Halogen (LSZH)

Armour: Galvanised Steel Wire

Sheath: Low Smoke Zero Halogen (LSZH)

Sheath Colour: Blue or Black

The maximum period of operation is 15years

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 65℃

Rated Voltage: 300/500V

Test Voltage (DC): 2000V Between Conductors

2000V Between Each Conductor and Armour

Reference Standards

BS 5308

PAS5308 part 1

BS EN/IEC 60332-3-24

General Characteristics

|

Conductor Size (mm2) |

Conductor Class |

Max. DCR (Ω/km) |

Max. Mutual Capacitance Values pF/m |

Max. Capacitance Unbalance at 1KHz (pF/250m) |

Max.L/R Ratio (μH/Ω) |

|

|

Cables with Collective Screens (except 1pair & 2pairs) |

1Pair & 2Pairs Cables Collectively Screened & All Cables with Individual Pair Screens |

|||||

|

0.5 |

1 |

36.8 |

75 |

115 |

250 |

25 |

|

1.0 |

1 |

18.4 |

75 |

115 |

250 |

25 |

|

0.5 |

5 |

39.7 |

75 |

115 |

250 |

25 |

|

1.5 |

2 |

12.3 |

85 |

120 |

250 |

40 |

Identification of Cable Pairs

|

Pair No. |

Colour |

Pair No. |

Colour |

||

|

1 |

Black |

Blue |

11 |

Black |

Red |

|

2 |

Black |

Green |

12 |

Blue |

Red |

|

3 |

Blue |

Green |

13 |

Green |

Red |

|

4 |

Black |

Brown |

14 |

Brown |

Red |

|

5 |

Blue |

Brown |

15 |

White |

Red |

|

6 |

Green |

Brown |

16 |

Black |

Orange |

|

7 |

Black |

White |

17 |

Blue |

Orange |

|

8 |

Blue |

White |

18 |

Green |

Orange |

|

9 |

Green |

White |

19 |

Brown |

Orange |

|

10 |

Brown |

White |

20 |

White |

Orange |

PAS/BS5308 Part 1 Type 2: Collectively Screened Armoured

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

||||

|

1 |

0.5 |

1 |

0.5 |

1.3 |

9.7 |

|

2 |

0.5 |

1 |

0.5 |

1.3 |

10.5 |

|

5 |

0.5 |

1 |

0.5 |

1.4 |

15.2 |

|

10 |

0.5 |

1 |

0.5 |

1.6 |

19.7 |

|

15 |

0.5 |

1 |

0.5 |

1.6 |

21.8 |

|

20 |

0.5 |

1 |

0.5 |

1.7 |

25.0 |

|

1 |

1 |

1 |

0.6 |

1.3 |

10.8 |

|

2 |

1 |

1 |

0.6 |

1.4 |

12.0 |

|

5 |

1 |

1 |

0.6 |

1.5 |

18.7 |

|

10 |

1 |

1 |

0.6 |

1.7 |

23.3 |

|

15 |

1 |

1 |

0.6 |

1.8 |

27.1 |

|

20 |

1 |

1 |

0.6 |

1.8 |

30.2 |

|

1 |

0.5 |

5 |

0.6 |

1.3 |

10.4 |

|

2 |

0.5 |

5 |

0.6 |

1.3 |

11.3 |

|

5 |

0.5 |

5 |

0.6 |

1.5 |

16.9 |

|

10 |

0.5 |

5 |

0.6 |

1.6 |

21.9 |

|

15 |

0.5 |

5 |

0.6 |

1.7 |

25.4 |

|

20 |

0.5 |

5 |

0.6 |

1.8 |

28.1 |

|

1 |

1.5 |

2 |

0.6 |

1.4 |

11.9 |

|

2 |

1.5 |

2 |

0.6 |

1.4 |

13.3 |

|

5 |

1.5 |

2 |

0.6 |

1.6 |

21.1 |

|

10 |

1.5 |

2 |

0.6 |

1.8 |

27.4 |

|

15 |

1.5 |

2 |

0.6 |

1.9 |

31.2 |

|

20 |

1.5 |

2 |

0.6 |

2 |

34.7 |

PAS/BS5308 Part 1 Type 2: Individually & Collectively Screened Armoured

|

No. of Pairs |

Conductor |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

|

|

Size (mm2) |

Class |

||||

|

2 |

0.5 |

1 |

0.5 |

1.4 |

13.1 |

|

5 |

0.5 |

1 |

0.5 |

1.5 |

15.7 |

|

10 |

0.5 |

1 |

0.5 |

1.6 |

21.3 |

|

15 |

0.5 |

1 |

0.5 |

1.7 |

24.7 |

|

20 |

0.5 |

1 |

0.5 |

1.8 |

27.2 |

|

2 |

1 |

1 |

0.6 |

1.4 |

14.9 |

|

5 |

1 |

1 |

0.6 |

1.5 |

19.0 |

|

10 |

1 |

1 |

0.6 |

1.7 |

26.0 |

|

15 |

1 |

1 |

0.6 |

1.8 |

29.5 |

|

20 |

1 |

1 |

0.6 |

1.9 |

32.7 |

|

2 |

0.5 |

5 |

0.6 |

1.4 |

14.3 |

|

5 |

0.5 |

5 |

0.6 |

1.5 |

18.1 |

|

10 |

0.5 |

5 |

0.6 |

1.7 |

24.6 |

|

15 |

0.5 |

5 |

0.6 |

1.8 |

27.7 |

|

20 |

0.5 |

5 |

0.6 |

1.9 |

30.6 |

|

2 |

1.5 |

2 |

0.6 |

1.5 |

17.6 |

|

5 |

1.5 |

2 |

0.6 |

1.6 |

21.5 |

|

10 |

1.5 |

2 |

0.6 |

1.8 |

29.7 |

|

15 |

1.5 |

2 |

0.6 |

1.9 |

33.6 |

|

20 |

1.5 |

2 |

0.6 |

2.1 |

38.3 |